Canusa DDX

The DDX – Directional Drilling Kit is a high performance system designed to protect welded joints on PP, PE and FBE coated pipelines in directional...

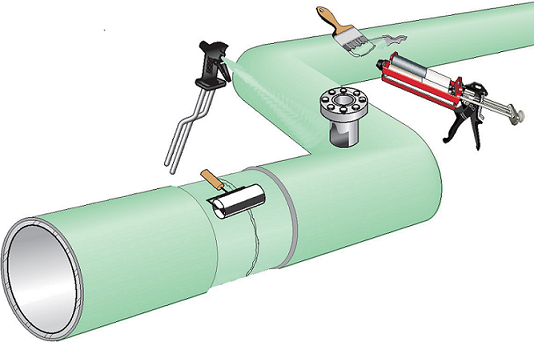

The DDX – Directional Drilling Kit is a high performance system designed to protect welded joints on PP, PE and FBE coated pipelines in directional drilling applications. The DDX system consists of the following key components:

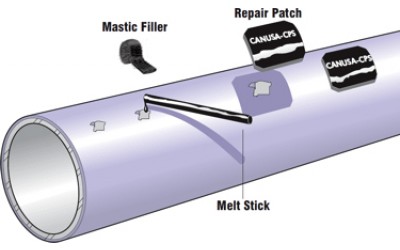

Force-cure epoxy primer applied to steel for maximum corrosion protection. Epoxy primer is only required for 3-layer applications.

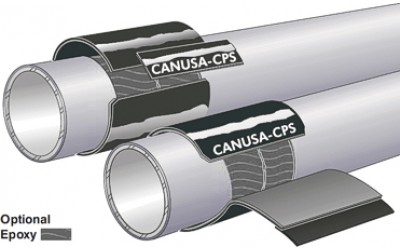

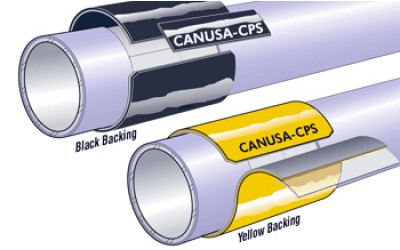

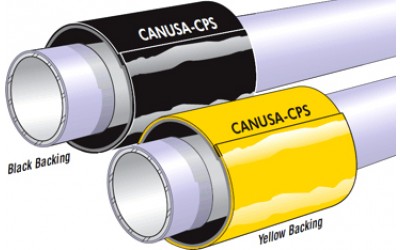

Primary sleeve composed of high shear strength adhesive, a protective heat shrinkable HDPE backing, and a pre-attached closure patch.

Sacrificial sleeve incorporated to protect the leading edge of the underlying primary sleeve during pullthrough operation.

In addition to providing effective protection against pull-through forces that occur during the directional drilling operation, Canusa’s DDX is a multi-layer system that provides superior corrosion protection at pipeline weld joints.