ClockSpring|NRI Casing Spacer

The CS|NRI Casing Spacer is a unidirectional fiberglass sleeve sized for a specific pipe diameter to center pipe in casings during installations under roads, at...

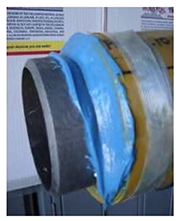

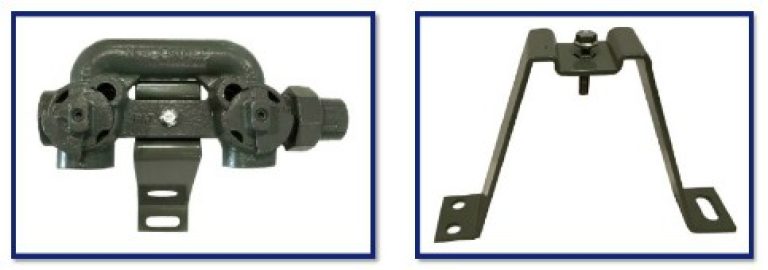

The CS|NRI Casing Spacer is a unidirectional fiberglass sleeve sized for a specific pipe diameter to center pipe in casings during installations under roads, at river and railroad crossings, and in downhole applications. Casing Spacers are an extremely robust solution that eliminates traditional integrity issues that can occur when pipes are pulled through casings, protecting the pipe from damage and reducing construction time and future maintenance costs.

BENEFITS:

• Limits movement of pipe at the ends of casing

• Acts as a bumper for wave action on cased pipe

• Reduces pulling friction

• Eliminates coating wear

• Minimizes deflection

• Provides electrical insulation

• Conforms tightly to pipe

• Slides into place with ease

• Installs without disrupting operations

• No special tools to install

• No environmental hazards

• No hot work

to receive your quote.

to receive your quote.