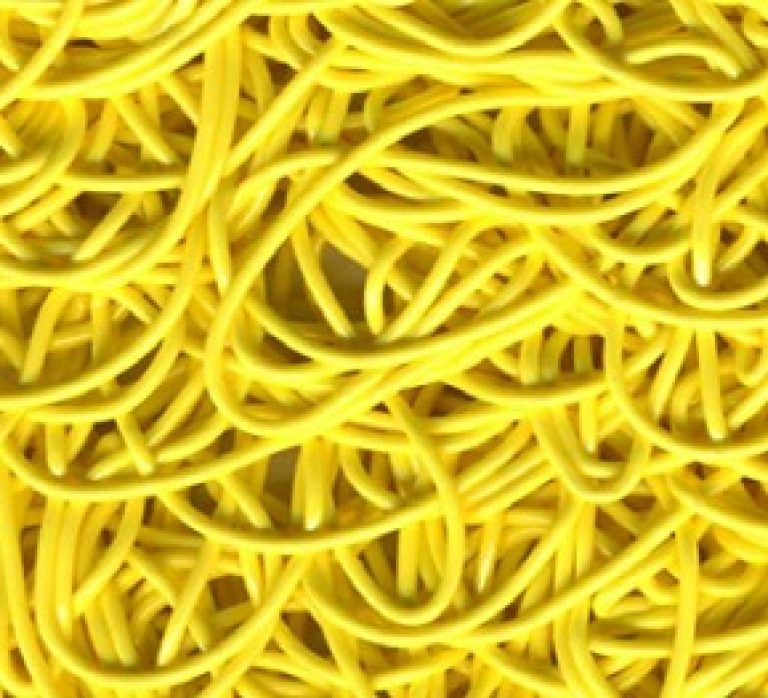

Tapecoat M50 RC (50 MILS)

Tapecoat M50 is a 50 Mil Gray polypropylene mesh-backed, cold applied, below grade coating designed to provide superior soil stress resistance to protect against corrosion...

Tapecoat M50 is a 50 Mil Gray polypropylene mesh-backed, cold applied, below grade coating designed to provide superior soil stress resistance to protect against corrosion and electrolysis on metal substrates. The Tapecoat M50 has an integrated primer in the adhesive which allows for faster application as there is no need to apply a separate primer when application temperatures are above 40°F. Appropriate for coating small to large diameter pipe, bends and metal structures, Tapecoat M50 is especially well suited for reconditioning field coated pipe and coating pipe in areas with high soil stresses.

to receive your quote.

to receive your quote.