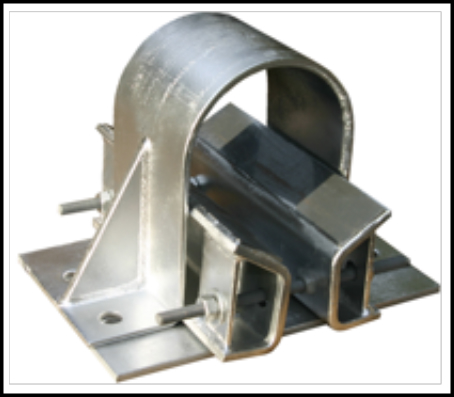

Adjustable Roller Stands, used in conjunction with Non-Conductive Rollers, offer an alternative to the epoxy type pipe chocks for preventing or correcting crevice corrosion problems....

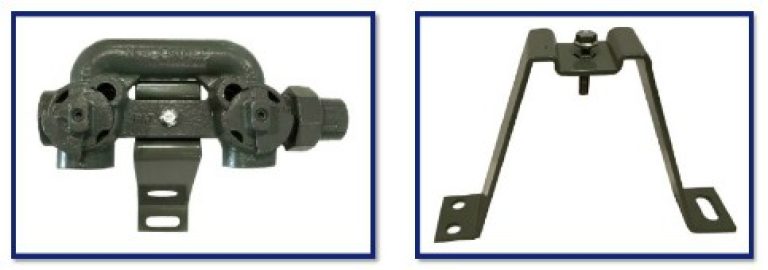

Adjustable Roller Stands, used in conjunction with Non-Conductive Rollers, offer an alternative to the epoxy type pipe chocks for preventing or correcting crevice corrosion problems. The polyurethane based Non-Conductive Rollers will not abrade the pipe’s coating and allows moisture to drain away from the bottom of the pipe. Non-Conductive Rollers do not contact enough of the pipe surface to allow moisture or organic materials (grass clippings, leaves, pine needles, etc) to collect at the pipe roller interface. Non-Conductive Rollers are particularly useful on pipes that show significant expansion and contraction.

The Adjustable Pipe Roll Stand generally includes a galvanized cast iron base, steel plate, adjusting bolts and Non-Conductive Roller with stainless steel sleeve. The base can also be fabricated from carbon or stainless steel to standard or non-standard specifications. Available for pipe sizes 2” through 24”.

A.Y. McDonald Mfg. Co. is known in the gas industry for its wide variety of house piping valves, gas meter valves, and curb valves. Their products represent...

A.Y. McDonald Mfg. Co. is known in the gas industry for its wide variety of house piping valves, gas meter valves, and curb valves. Their products represent a new era of offerings that are consistent with their state-of-the-art manufacturing facilities and efforts to enhance their gas distribution products. Please see the catalog or contact us for more information on: High Pressure Ball & Plug Style, Curb Valves, Ball Style Outlet Angle Valves, Meter Bars, Cast Iron Meter Bars, By-Pass Meter Bars, Re-Lubrication Tools, Insulated & Non-Insulated Swivels & Accessories such as Meter Nuts, Plugs, Gaskets & Unions.

The Bristle Blaster® accelerator bars create the basis for the high performance capability of the Bristle Blaster® technology. The extremely resistant bars are available in two...

The Bristle Blaster® accelerator bars create the basis for the high performance capability of the Bristle Blaster® technology. The extremely resistant bars are available in two lengths and material types.

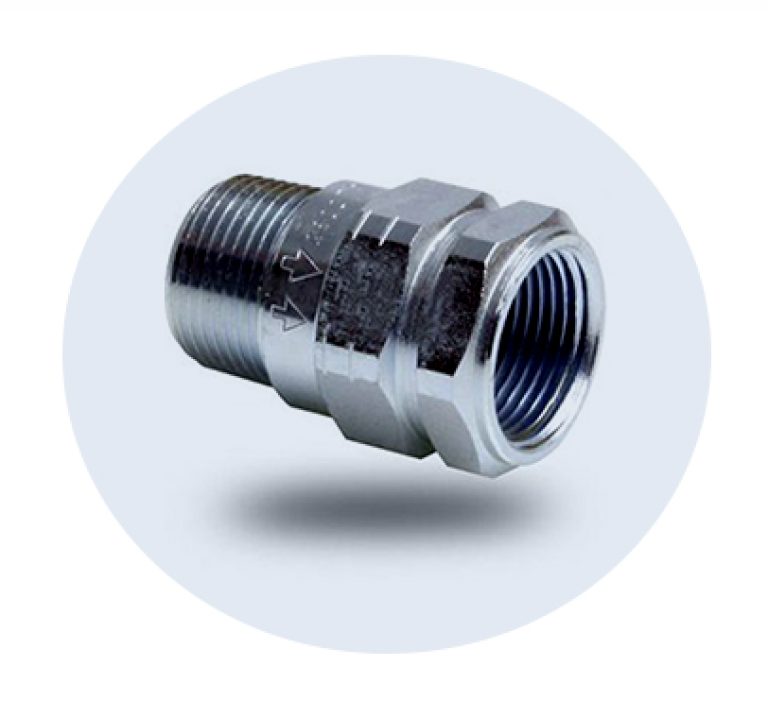

For long-term dependability, experts choose the ALFA Monolithic Isolation Joint which is welded into place for a permanent solution. • Industry proven double O-ring seals...

For long-term dependability, experts choose the ALFA Monolithic Isolation Joint which is welded into place for a permanent solution.

• Industry proven double O-ring seals standard (available with triple O-ring seals based on application)

• Standard O-ring material ‘NBR’ (other materials optional based on application)

• O-ring design in accordance with ASTM D2240, ASTM D412, ASTM D395, ASTM D1329, ASTM D1817 and ASME VIII Div.1 appendix II.

• Isolating elements: NEMA G10/G11 – ASTM D709 Class H

• Back seal: silicone neutral low module/filler isolator: epoxy resin cold cured

• Internal and external coating of amine cure epoxy resin

• Pipe pups API 5L X52 or API 5L Grade B (other materials available as per customer requirements)

• Welding in accordance with ASME IX

Atlas Wedge Clamps are used to provide a safe and reliable means to anchor and level piping systems. The wedge assembly provides easy height and level adjustment while...

Atlas Wedge Clamps are used to provide a safe and reliable means to anchor and level piping systems. The wedge assembly provides easy height and level adjustment while the clamp secures the host pipe to the foundation. Atlas Wedge Clamps isolate the pipe from the clamp using fiberglass reinforced plastic (FRP) pads which prevents any metal to metal contact. Inspection of the pipeline is easily accomplished by simply lowering the wedge assembly. The Atlas Clamp can be directly mounted to a variety of foundations including skids and concrete using the appropriate hardware. The optional base plate assists in securing the wedge block assembly to the foundation.

Note: Anchor bolts are not provided.

Manufactured to the highest quality standards, Atlas clamps will save both time and labor which will result in increased profitability on your next project.

Atlas Pipe Supports are used to provide a safe and reliable means to support and level piping systems. The Atlas supports incorporate a unique I-beam...

Atlas Pipe Supports are used to provide a safe and reliable means to support and level piping systems. The Atlas supports incorporate a unique I-beam stanchion design and are constructed with the mechanical integrity to meet the most demanding requirements. Atlas supports isolate the pipe from the support using a fiberglass reinforced plastic (FRP) pad which prevents metal to metal contact. Inspection of the pipeline is easily accomplished by simply removing the U-bolts and lowering the support head.

Atlas III Pipe Supports provide 16” to 36” of vertical adjustment and are available in customized head configurations. Height adjustment is made easy using the base pin for larger adjustment increments or the threaded rod for finer adjustment.

Manufactured to the highest quality standards, Atlas Pipe Supports will save both time and labor which will result in increased profitability on your next project.

Pin brazing is used to ensure a safe electrical connection to different types of metal. The pin brazing process is ideally suited for many applications...

Pin brazing is used to ensure a safe electrical connection to different types of metal. The pin brazing process is ideally suited for many applications including continuity bonding between pipes, connecting measuring and test cables, and the installation of sacrificial anodes and test stations.

The Barlow Flange Isolation Joint is welded into place for a permanent solution and designed to the highest possible standards using precision machined heavy duty...

The Barlow Flange Isolation Joint is welded into place for a permanent solution and designed to the highest possible standards using precision machined heavy duty components.

FEATURES:

• Thicker dielectric sleeves (1/8″) machined to precise, close tolerance dimensions, both length and diameter

• Flange bolt holes line reamed to provide perfect alignment and close tolerance fit to the dielectric sleeves

• Flange studs machined from Alloy Steel and heat treated to ASTM Designation A-193-52T Grade B-7 resulting in superior strength and greater resistance to stress-induced elongation

• Coupling nuts machined from Alloy Steel and heat treated to ASTM Designation A-194 Class 2-H

• Precision machined steel washers, flat, parallel and counterbored allowing for square alignment and clearance for the dielectric sleeves

• Flange gasket precision cut for ideal fit with small projection into the stream to prevent bridging of the joint inside the pipe

• Precise assembly with accurate torquing carried out in sequential pattern followed by retorquing after 24 hours

• Flange gap sealed with epoxy resin to prevent contamination and electrical shorting

• Dielectric strength test (minimum) 5 kV at 50 hz for 1 minute (dry air)