The Bristle Blaster® System is an innovative bristle blasting process that removes corrosion and generates an anchor profile by using a specially designed rotary bristle...

Read more

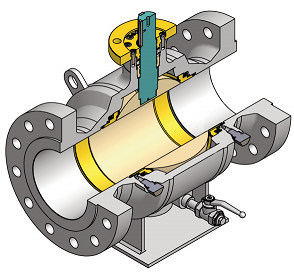

The Bristle Blaster® System is an innovative bristle blasting process that removes corrosion and generates an anchor profile by using a specially designed rotary bristle tool. This tool consists of hardened wire bristle tips that are bent forward and are dynamically tuned to a hand-held power tool which operates at approximately 3,500 rpm. Most common uses include: coating removal, paint removal, scale removal, weld cleaning, surface decontamination, surface preparation, texturing applications, and corrosion removal.

Please click here to view a video on how to operate the Bristle Blaster®

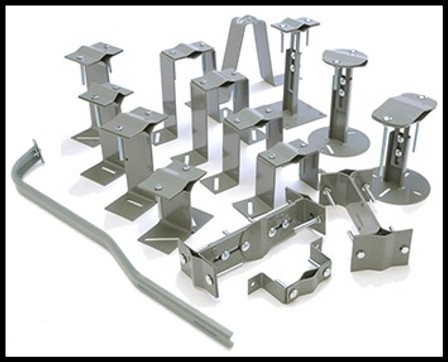

KIT INCLUDES:

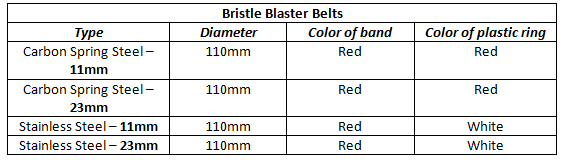

SP-647-02 CARBON SPRING STEEL – 11 & 23 mm Belts – Bristle Blaster Pneumatic Kit includes: (1) Pneumatic drive unit, (2) adaptors 11mm & 23mm, (5) carbon steel Bristle Belt 11mm, (5) carbon steel Bristle belt 23mm, (2) MBX In-line Air Pressure Regulators 11mm & 23mm, (1) dust exhaust system, (1) Accelerator Bar 11mm & (1) Accelerator Bar 23mm

SP-649-02 STAINLESS STEEL – 11 & 23 mm Belts – Bristle Blaster Pneumatic Kit includes: (1) Pneumatic drive unit, (2) adaptors 11 & 23mm, (5) stainless steel Bristle Belt 11mm, (5) stainless steel Bristle belt 23mm, (2) MBX In-line Air Pressure Regulators 11mm & 23mm, (1) dust exhaust system, (1) Accelerator Bar 11mm & (1) Accelerator Bar 23mm

Read less